Le istituzioni, i cittadini e le aziende europee stanno affrontando una sfida senza precedenti: quella della lotta al cambiamento climatico.

Con temperature in aumento, eventi meteorologici estremi sempre più frequenti e una crisi ambientale in crescita, l’urgenza di agire è diventato un imperativo.

In questo contesto, il ruolo delle aziende nell’adozione di pratiche sostenibili è diventato cruciale.

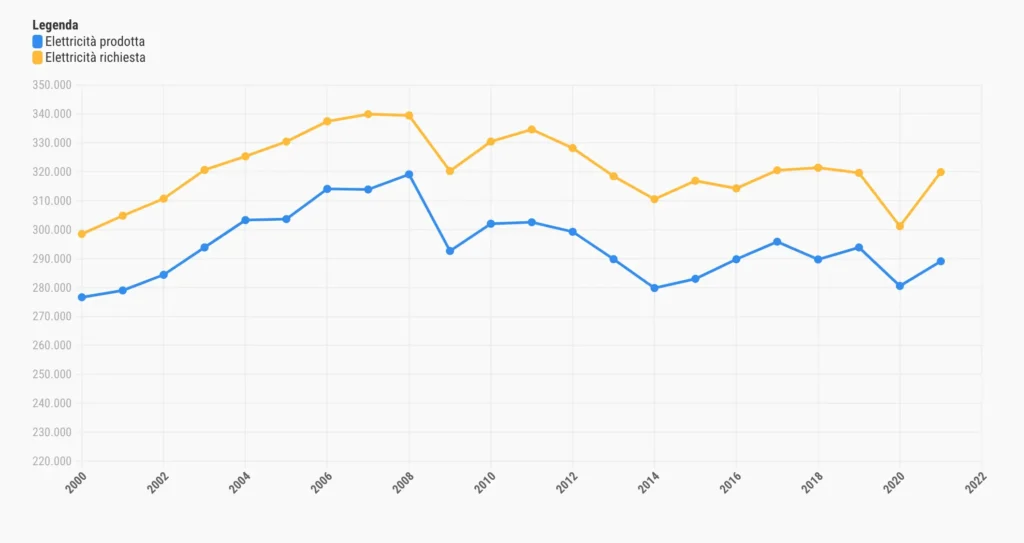

Negli ultimi anni è cresciuta, anno dopo anno, la richiesta di energia elettrica, domanda proveniente soprattuto dal settore industriale.

In Italia sono stati consumati, nel 2021, quasi 320mila Gwh di energia elettrica (300,9 miliardi di kilowattora). Con un aumento del 6% rispetto al 2020, che ha riguardato soprattutto il settore industriale (+8,2%).

Come si è sviluppato questo intervento di efficienza energetica della AL.PI soles?

Dal rifacimento del tetto all’installazione di pannelli fotovoltaici

Uno degli interventi principali è stato il rifacimento della copertura, sostituendo i vecchi pannelli in fibrocemento con pannelli sandwich, una copertura coibentata utilizzata generalmente per i tetti composti da due lastre resistenti in metallo o legno, mentre all’interno presentano uno strato di materiale leggero, ma isolante.Perchè abbiamo deciso di installare i pannelli sandwich?

L’utilizzo di tali pannelli è stato motivato dai vantaggi che il loro utilizzo offrono:

- elevata resistenza al fuoco, alle sollecitazioni, all’usura e agli agenti atmosferici (elevata durata nel tempo);

- leggerezza, poco peso sulla struttura che li ospita;

- poca dispersione di calore e risparmio energetico;

- possibilità di installazioni anche su materiali già esistenti;

- facili da installare, spesso dotati di incastro maschio-femmina;

- customizzabili a seconda dell’esigenza e dell’effetto estetico desiderato.

L’installazione di tali pannelli ha preparato il terreno per l’installazione di un impianto fotovoltaico all’avanguardia per AL.PI soles.

Tale intervento ci ha permesso di installare sul tetto della nostra azienda 361 pannelli solari ad alte prestazioni: un sistema fotovoltaico da 450 kW.

Questo impianto, alimentato dal sole, è progettato per produrre un’energia pulita stimata in 540.000 kWh all’anno, di cui almeno il 70% sarà utilizzato internamente all’azienda.

Ma gli interventi di efficienza energetica non termina qui.

Batterie di accumulo e ricarica per veicoli elettrici: verso l’autosufficienza.

Per massimizzare l’autoconsumo dell’energia prodotta, ALPIsoles ha installato una batteria di accumulo da 23,2 kWh, consentendo un aumento significativo dell’autoconsumo fino al 79%. Inoltre, l’azienda ha realizzato una colonnina di ricarica per auto elettriche con doppia alimentazione, con una potenza massima di 22 kW per un totale di 44 kW, dimostrando un impegno tangibile e concreto verso la mobilità sostenibile.

Dal controllo dei consumi alla riduzione delle emissioni: un passo avanti verso l’Industria Sostenibile.

L’intervento di efficienza energetica realizzato dalla AL.PI soles non ha riguardato solo l’implementazione di tecnologie avanzate per il risparmio energetico ma anche l’ottimizzazione dei processi esistenti. ALPIsoles ha implementato un sistema di controllo per l’aspirazione dei fumi, regolando le aperture delle bocchette in base al ciclo di stampaggio. Inoltre, l’azienda ha sostituito l’impianto di aspirazione delle polveri con uno più efficiente, riducendo la potenza installata e migliorando l’efficienza complessiva.

Monitoraggio dei Consumi: La Chiave per il Futuro Energetico

Infine, ALPIsoles ha promosso la trasparenza e la consapevolezza energetica attraverso l’installazione di un sistema di monitoraggio dei consumi. Questo strumento fornirà all’azienda dati in tempo reale sui consumi energetici, permettendo un’ottimizzazione continua e un controllo più preciso.

Verso un futuro più sostenibile

Con questi interventi, ALPIsoles non solo ridurrà il suo impatto ambientale, ma si avvicinerà anche all’obiettivo di diventare un’azienda energeticamente autosufficiente.

La somma di questi interventi verso l’efficienza e l’indipendenza energetica porteranno l’azienda ad un risparmio importante di energia e di emissioni evitate con i seguenti dati:

- Energia primaria risparmiata 378 MWh/anno;

- Energia risparmiata 32 tep/anno;

- Emissioni evitate 309.906 kg in CO2 equivalente/anno.

Il nostro impegno – afferma Demetrio Biancucci, Co-Founder di AL.PI soles – è quello di creare un circuito virtuoso per ridurre gli scarti, accettando la sfida di produrre zero scarti e produrre sempre piu con energie rinnovabili, aumentare significativamente l’indipendenza energetica per garantire ai nostri figli e al nostro territorio un futuro più pulito.