The footwear sector offers an extremely wide range of soles for shoes, from accident-prevention models, via sports and orthopedic variants, all the way to those for classic sneakers.

There are innumerable different types available on the market, but have you ever asked yourself how a sole is actually made?

With this article, we’ll try to explain it to you as clearly as possible!

When we’re talking about shoes, it’s important to know that the main part of the shoe is what’s called the “last,” which will go on to determine everything from the fit of the shoe, the size of the heel, and the height of the collar, all the way to the style. As a consequence, it’s clear that everything starts with the sole.

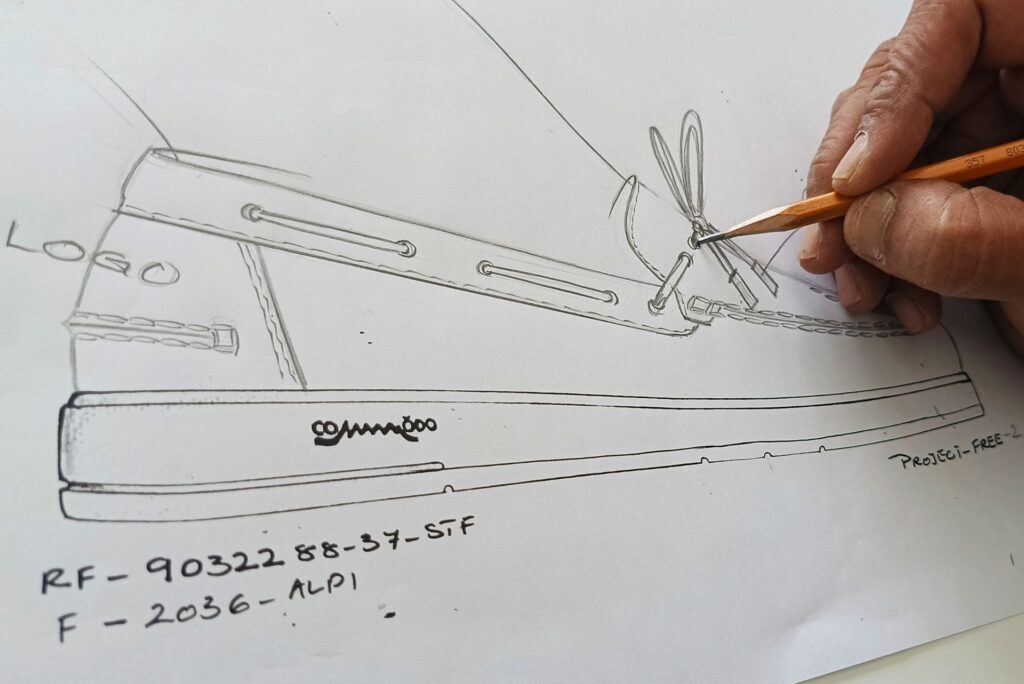

Phase 1: the sketch of the shoe.

We start from the sketch of the shoe: it is essential, in that it is based on crucial technical and aesthetic elements, which take into consideration both the design and the volume.

Phase 2: the creation of the last.

From the sketch we move onto the second phase, which is the creation of the “last.”

In this phase, the volumes and measurements are quantified – these are necessary to make the shoe as comfortable and easy to wear as possible for the end customer.

Phase 3: design of the upper.

The third step is to study the details and the parts that compose the upper: a series of elements will then be defined, such as the materials (leather, fabric, lining, etc…), the accessories and the colors

One factor that should not be underestimated is that all of these components will add volume to the original last.

Phase 4: definition of the perimeter of the sole.

Once the thicknesses have been defined and a first assembly test has been carried out, we can move towards the fourth phase of our process of constructing a sole – the definition of the precise perimeter of the sole, since it has to match the last (complete with the upper) perfectly. This operation defines the internal template of the sole.

Phase 5: design of the sole.

It is during the fifth phase that the design proper of the sole begins: after verifying its feasibility, identifying the most suitable material(s), setting the template, the design, and the last, we then move forward by going back to the initial sketch of the shoe, from which our process all began.

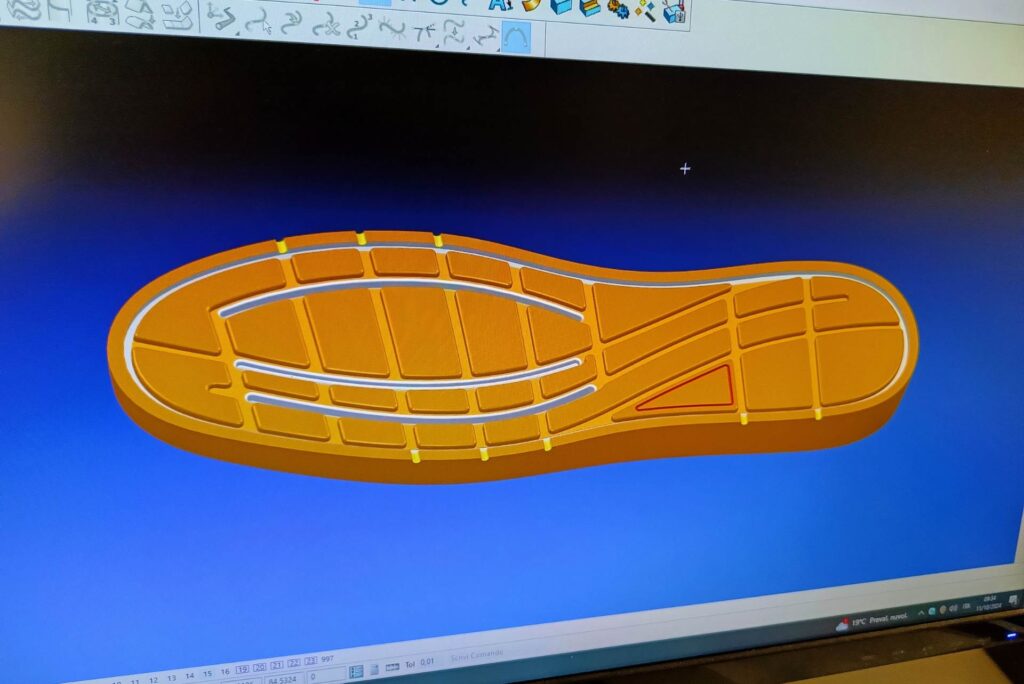

Phase 6: production of the maquette (preliminary model).

Having reached the sixth phase, we move on with the production of the maquette, which is a model that will represent on a 1:1 scale the volume, design and details of the soul that we will then go on to manufacture. To create the maquette, there are various options: we can do so manually, through the use of rigid resins worked by expert craftspeople; or using CAD/CAM technologies, through which we can produce 3D simulations before manufacturing our maquette either by CNC machining or 3D printing (in this case, we can also use soft materials).

Phase 7: design and production of the pilot mold.

Once the maquette has been completed and approved, the subsequent step concerns the design and production of the pilot mold, taking account of the material with which the sole is to be manufactured: when we’re dealing with soles for high-quality footwear, rubber is often the first choice due to its excellent properties.

However, there are other types of materials such as TR (Thermoplastic Rubber), TPU (Thermoplastic Polyurethane), EVA (Ethylene-Vinyl Acetate), Polyurethane, etc. … as well as nEr+, a material recently developed by AL.PI. that offers the same physical and mechanical characteristics as rubber, but with an important form of added value: 20% lower weight; moreover, it is made with up to 30% recycled components, deriving from waste taken out of the waste cycle.

Dopo aver quindi determinato il materiale con il quale verrà realizzata la suola, si procede con la realizzazione dello stampo pilota normalmente nella taglia centrale che per un modello da donna corrisponde solitamente alla taglia 37 mentre da uomo alla taglia 42.

Phase 8: sampling.

We have now arrived at the final phase of our process. Having made the first mold, we will then produce the first sample, which is the first real simulation, on the basis of which we will then move ahead with the subsequent phase of preparation for production.

Once final approval of the prototype has been received, we will then reach the manufacturing stage proper.

AL.PI. is your ideal partner for the manufacture of soles for footwear, leveraging our thirty years of experience in the sector.

We support brands and companies that operate in international markets, helping them to create soles for their men’s, women’s and children’s shoes across different sectors of the footwear industry (sneakers, winter shoes, work shoes).

Contact us for a free-of-charge consultation on the design and manufacture of soles for your brand’s footwear. Our team of experts professionals is on hand to help you.